Not long after Dr. Ali Dhinojwala, chairman of The University of Akron Department of Polymer Science, unpeeled the secret (fine, clingy hairs) behind the remarkable adhesion of gecko feet, he and fellow researchers came up with a synthetic replica: carbon nanotubes. Now, five years after that initial discovery, the basis of the success of these nanotubes is published recently in an issue of the American Chemical Society's NanoLetters.

UA nano researchers Dr. Ali Dhinojwala, chairman of Department of Polymer Science, and graduate student Liehui Ge unpeel the secret to nanohair adhesion's powerful grip.

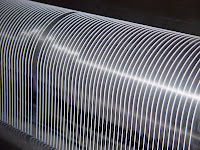

While the story of nanotubes is one of success, not all carbon nanotubes are equal, nor is the individual adhesion performance of each strand, according to Dhinojwala. Although Dhinojwala and UA polymer science graduate student Liehui Ge determined that these 8-nanometer-diameter carbon hairs - each 2,000 times smaller than the diameter of a human hair - adhere powerfully to glass and similar substrates, they furthered their research to learn why some strands have a firmer grip than others.

Getting a grip on adhesion

Findings by the UA scientists, in collaboration with Lijie Ci and Anubha Goyal, researchers with the Department of Mechanical Engineering and Materials Science at Rice University; Rachel Shi, UA Research Experience for Undergraduates (REU) intern; and L. Mahadevan, professor of applied mathematics and professor of organismic and evolutionary biology at Harvard University, reveal that the softer the nanotube, the greater its adhesion.

Fine hairs on the soles of gecko feet allow the lizards to climb vertical surfaces with ease. UA polymer researchers have discovered a synthetic glue (carbon nanotubes) with nearly four times the adhesion power of gecko hairs. Now the scientists reveal why the mimic version offers its remarkable staying power.

Using a combination of mechanics, electrical resistance and scanning electron microscopy (SEM) to study the contact between hairs of a large number of vertically aligned carbon nanotubes with glass or silicon substrates, the researchers found that soft nanotubes clasp and curve when pressure is applied, contributing to their adhesive strength.

"We found out that the diameter of the tubes is an important parameter for adhesion because we have to balance the adhesion and bending rigidity of the tubes," Ge says. "Also, if you apply a high pressure, the tubes bend and buckle and make a larger contact area with the surface, which is the reason for higher adhesion."

The dry adhesive, unlike liquid glue counterparts, promises successful use in extreme atmospheric and temperature conditions and in other applications that present challenges. "The carbon nanotube-based gecko adhesives are going to open up opportunities to using these materials on robots, to climb vertical walls, and could actually be used in outer space (vacuum condition) because these materials stick without any liquid glue," Dhinojwala says.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)