How Does Prevulcanisation Inhibitor Works?

John Woon (Senior Latex Consultant): The best way to control the vulcanization behaviour of the rubber is through careful choice of curatives and accelerator. Very often, for a more "plateau" and less scorchy cure, one normally uses sulphenamides while for intermediate scorch delay, MBT, MBTS or a blend of both are used.

In order to improve productivity, secondary accelerators such as thiurams and DPG are added to reduce the cure time. However this is achieved at the expense of optimal cure state and the final physical properties.

To prevent this problem, one could use "Prevulcanization Inhibitor" i.e. you can achieve the scorch safety you want without affecting the physical properties.

Here is how it works:

1) Sulphenamide reacts with sulphur forming a complex polysulphide

2) Polysulphide in turn reacts further with rubber, liberating MBT and forming rubber-polysulphides

3) MBT released act as a catalyst for the formation of intermediate polysulphides

3) Rubber-polysulphides then inter-react resulting in vulcanized rubber

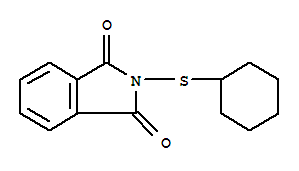

Prevulcaniszation Inhibitor (PI) mops up MBT by reacting stoichiometrically with it. Hence vulcanization is delayed until all the PI has been consumed.

I suggest you experiment with different levels (e.g. 0.1 to 0.4 phr) of PI. One good example of PI is Cyclohexylthio-phthalimide.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

0 Comments:

Post a Comment

<< Home