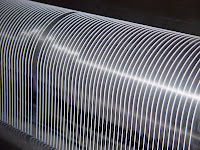

New Hydrogel Condoms ‘More Like Human Skin'

Researchers at the University of Wollongong in Australia who were awarded a grant from the Bill & Melissa Gates Foundation are furthering research into substances called tough hydrogels, which are currently used in medicine and robotics.

“We hope to deliver a condom that is safe and feels and looks better,” a UW release states. “It’s designed to feel more like human skin than latex rubber.”

The research team touts other benefits of hydrogel condoms, including invisibility and self-lubrication.

“That would eliminate problems with latex allergies and improper use of oil-based lubricants,” according to the release.

Dr. Sina Naficy, a polymer scientist working on the project, said the so-called “next generation condoms” could also be more environmentally friendly because the hydrogels are mostly made of water.

“Hydrogels can also be made to be biodegradable, which solves the problem of condom disposal,” according to the release........CLICK HERE to read the whole article

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)