Hartalega: We Are Not Polluters

Hartalega Holdings Bhd managing director Kuan Kam Hon, who called the allegations “baseless and a misrepresentation,” said he was disappointed that no clarification had been sought from the company over the claims.

“As a responsible public-listed company on Bursa Malaysia and a world-class manufacturer of nitrile gloves, we are compelled to put the record straight.

“We are very transparent and willing to clarify any doubt. We abide by local and international environmental regulatory standards.

“How can a company that receives so many international and local awards be in violation of environmental regulations?” he told reporters at a press conference here yesterday.

It was reported in the local media that the factory was allegedly causing air and water pollution. The factory had existed long before the residential area was built and there was a lack of a buffer zone between the two.

Kuan said officers from the Department of Environment, the Kuala Selangor Municipal Council, International Trade and Industry Ministry and the Malaysian Industrial Development Authority had visited Hartalega’s manufacturing facilities and confirmed its compliance with all building and environmental regulations.

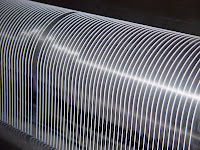

He said this included the use of environment-friendly biomass boilers, its various corporate social responsibility initiatives in Taman Suria and it spending over RM5mil annually to treat effluents and emissions to ensure that these met requirements.

He also handed out copies of support letters from local residents and businesses, including several village development and safety committees.

(Hartalega Q2 net profit up 42.3% - CLICK HERE for details)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)