Bloom problems of household gloves

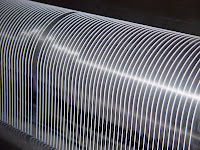

surface of rubber gloves?

JohnWoon: Bloom can be classified as "True Bloom" and "Bloom-like Phenomena". In order to ascertain whether your problem is due to true bloom, you have to ask yourself the following questions:

1)Does the bloom develop over time i.e. on storage?

2)Does it disappear on heating?

3)Can it be removed by wiping with solvent?

If the answers to these questions are all "Yes", you're having a true bloom problem.

For true bloom to occur, the chemicals concerned must have a limited but appreciable level of solubility in the rubber. Also, they must be present at a level or concentration greater than the said solubility at the temperature of use or storage.

Briefly the mechanism involves the crystallization of the chemical as the vulcanized rubber cools down. As the crystals grow within the rubber matrix, regions of strain around the crystals are formed. As a result, the tendency is for the crystals to move towards regions where there is lesser strain, namely the rubber surface.

Curatives that bloom are mainly sulphur, Zinc dithiocarbamate (diethyl being the worst culprit) and some thiazoles.

Ratios of sulphur:accelerator:ZnO:antioxidant, types of accelerators and degree of cure are all important factors to consider in order to prevent blooming. Chemical blooms are the major complaints from users of household gloves due to Type IV allergy reaction, namely delayed contact dermatitis.

One would usually observe a badly bloomed product to have lesser surface tack compared to one that has no bloom for obvious reason. Of course the resultant tackiness with a "non-blooming" formulation could be easily overcome by other means.

Having said this, you have to be aware also of the possibility of "bloom-like" problems due to other factors such as modified bloom (e.g. reaction between Zinc stearate and water vapour), surface degradation, filler bloom, surface contamination, frosting etc.

More in-depth recommendations with suggested formulation to overcome blooming and tackiness problems, improving heat ageing and detergent resistance are available from JohnWoon Consultants.

You are at the site for answers and solutions to all your problems in natural rubber latex processing and manufacturing of medical gloves, condoms, catheters, baby teats and baby pacfiers.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)