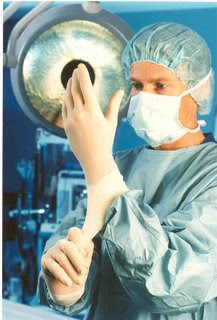

How did FDA start to get itself involved in the regulation of medical gloves?

JohnWoon:FDA's initial focus was solely on the regulation of drugs and materials coming into contact with food. But this changed with the introduction of the Medical Device Amendments to the Federal Food, Drug, and Cosmetic (FFD&C) Act in 1976. This allows FDA to extend its regulations to cover the proper use, effectiveness, and safety of all medical devices, including disposable medical gloves and condoms.

Although FDA does not write standards for medical devices, it participates in standard-writing committees. It recognizes guidelines written by other parties such as American Society of Testing and Materials (ASTM), the American Association of Medical Instrumentation (AAMI) and United States Pharmacopoeia (USP). FDA uses the published standards when evaluating medical devices for the marketplace.

FDA's requirement that all medical glove manufacturers shall meet ASTM guideline D5151 for the detection of holes in disposable exam gloves is one good example.

ASTM is a nonprofit organization that meets and writes standards for a wide range of products, services, and materials for the benefits of consumers, manufacturers, government representatives etc. Its guidelines are recognized very widely even outside USA. Since FDA gives a lot of importance to these guidelines, glove manufacturers must conform to these standards to meet FDA requirements for the particular types of medical gloves they sell.

ASTM revises its standards in response to changes in industry and also the consumer and regulatory needs. ASTM publishes annually more than 10,000 standards that are compiled in more than 70 volumes of Annual Book of ASTM Standards.

As far as medical gloves are concerned, ASTM's scientifically designed tests are carried out to accurately assess the quality of the products made from a variety of manufacturing approaches, formulations and raw materials. These include water leak, air inflation, chemical permeation, tensile strength, V-tear Test, trouser tear, puncture resistance, skin irritation and sensitization tests.

You are at the site for answers and solutions to all your problems in natural rubber latex processing and manufacturing of medical gloves, condoms, catheters, baby teats and baby pacfiers.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)